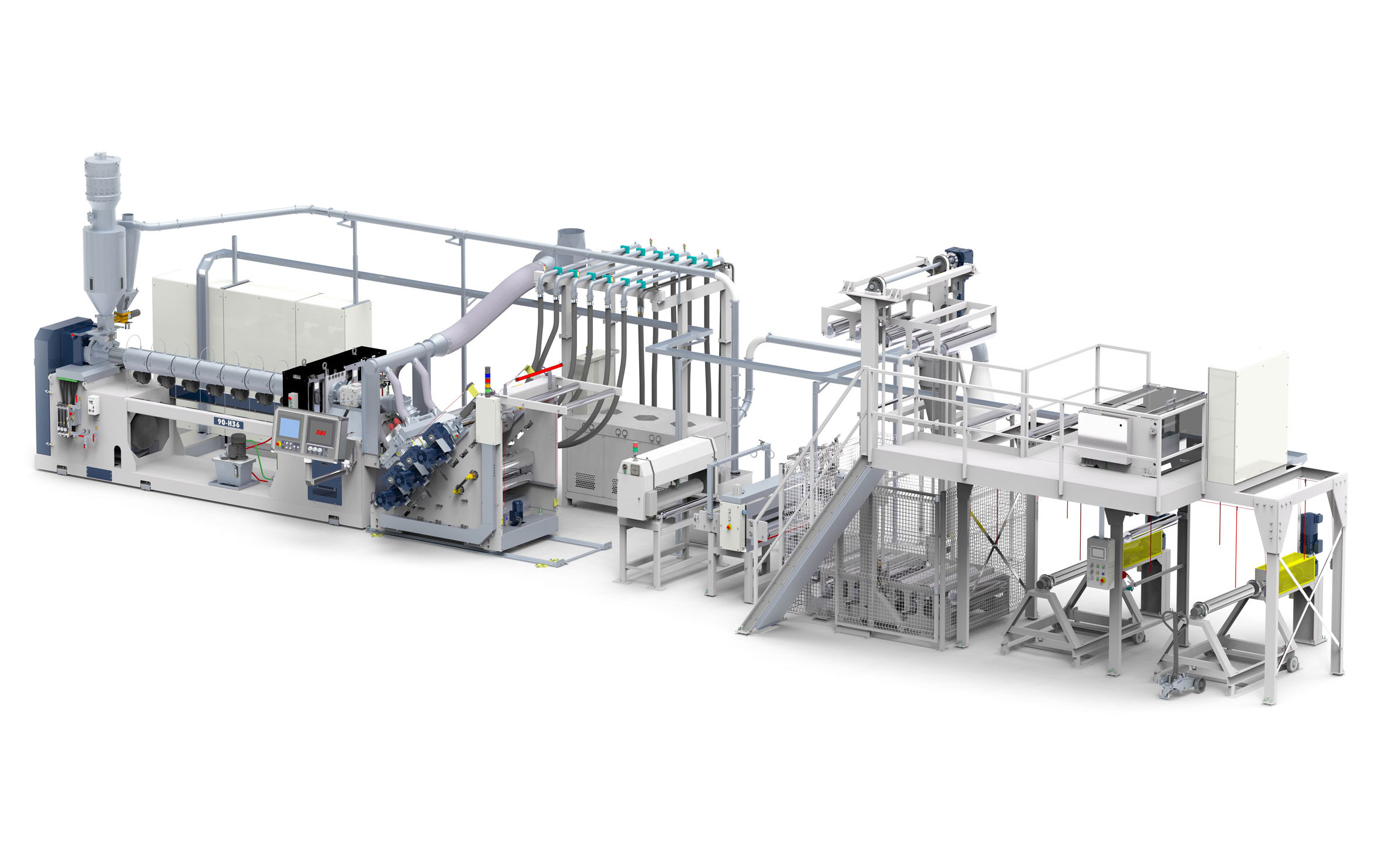

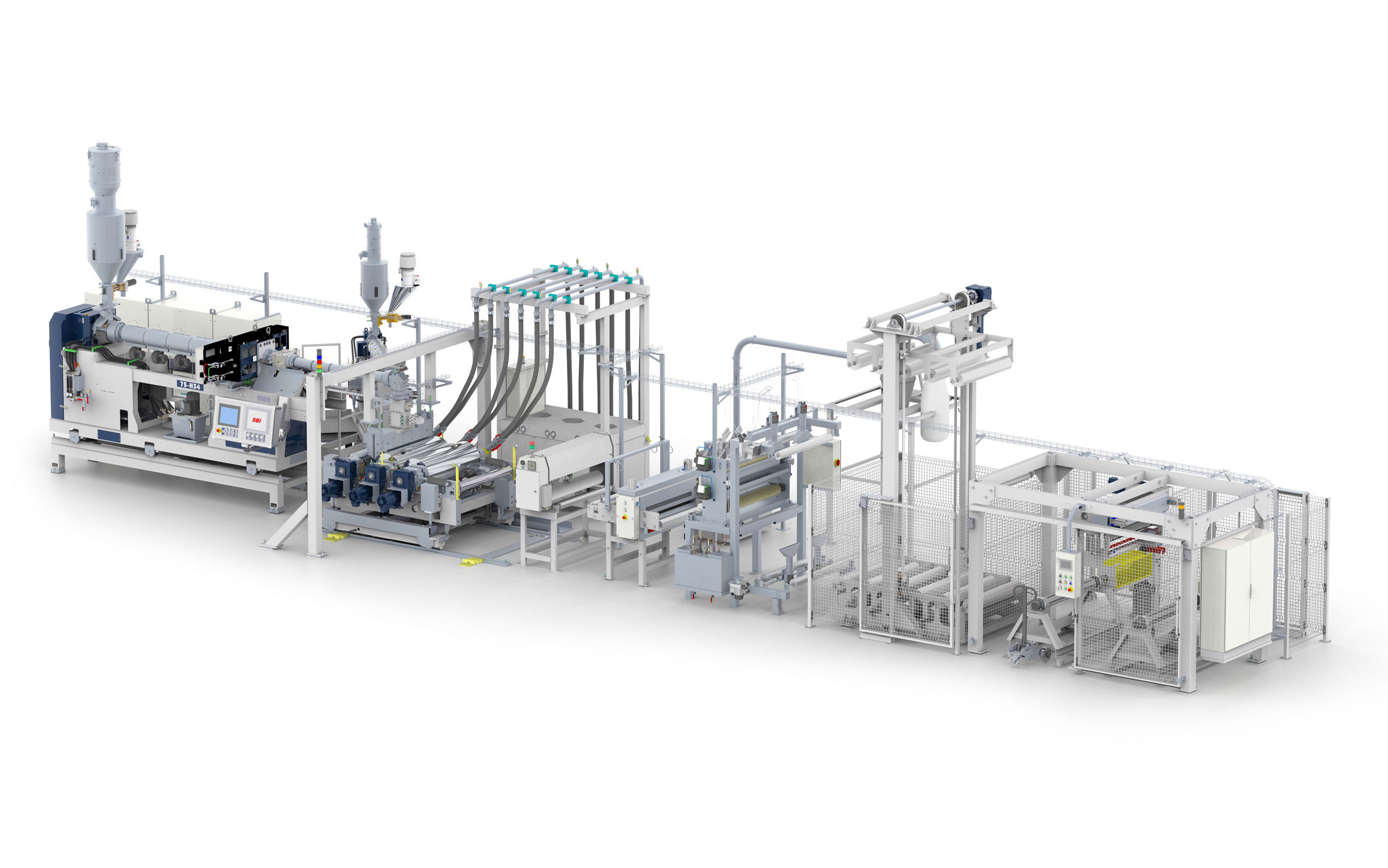

MEAF Machines B.V. is your one-stop-shop manufacturer for sheet extrusion equipment for a wide variety of raw materials. MEAF offers the possibility to deliver turnkey projects (including auxiliaries) and can even undertake customized, in-house retrofits of existing production lines!

Meaf Machines B.V.

Industrieweg 10

4401 LB Yerseke, The Netherlands

VAT number NL00.61.31.438.B01

Register No.22025279 Chamber of Commerce

MEAF Machines B.V. is your one-stop-shop manufacturer for sheet extrusion equipment for a wide variety of raw materials. MEAF offers the possibility to deliver turnkey projects (including auxiliaries) and can even undertake customized, in-house retrofits of existing production lines!

Meaf Machines B.V.

Industrieweg 10

4401 LB Yerseke, The Netherlands

VAT number NL00.61.31.438.B01

Register No.22025279 Chamber of Commerce